Development

Outline

Unleashing

"surficial evolution"

into the world

Our Strength

01

Free thinking unbridled by conventional knowledge

Our employees are always encouraged to conceive unique ideas and try out new and unique material compositions and formulations (to achieve softness and non-abrasiveness, or water repellency and anti-fogging, etc.) without paying too much attention to seeming contradictions and conventional knowledge. They are trained to notice the slightest of clues and hints to realize novel conceptions and transform thought processes.

02

Outstanding R&D capability to identify and meet the needs of the times ahead of the competition

We are engaged in cutting-edge technological development to meet the needs of the times ahead of the competition by combining polymer material technology and unique ideas. Such development activities are aimed at creating future-oriented products that can become NATOCO's mainstay in the coming age.

03

High analytical capability for addressing various client issues

We are focused on the evaluation and analysis of polymer materials involving morphological observation, surface analysis, composition analysis, etc. Its analytical capability grounded in decades of experience along with high-performance analyzers allows us to provide solutions to clients’ issues.

Activities

This section provides information on our R&D activities

that allow it to provide the types of products and technological solutions

that only it can.

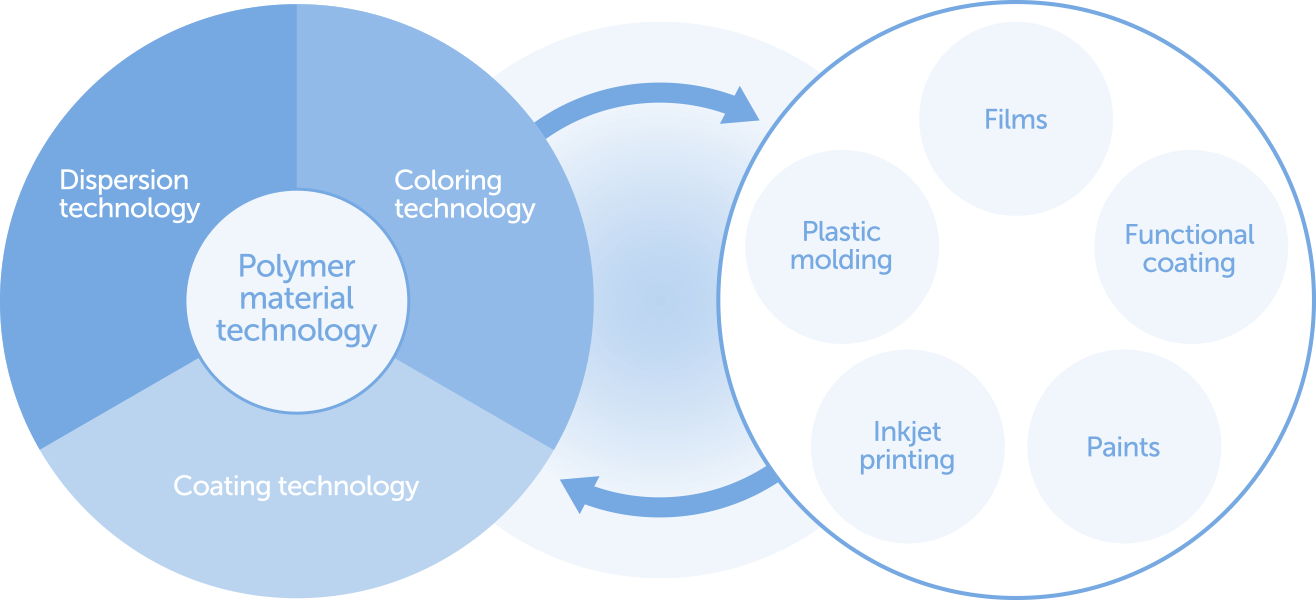

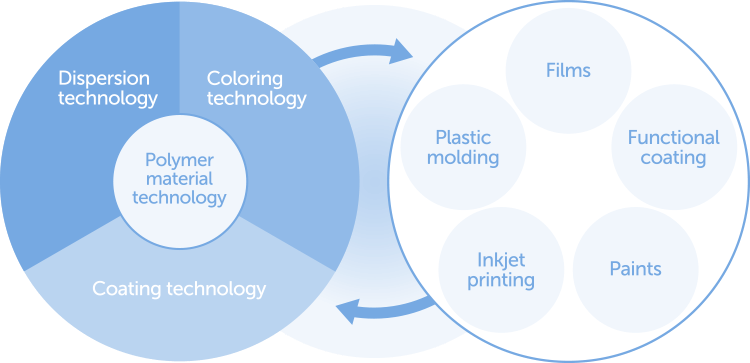

Elemental technology development

We have been perfecting its fundamental paint technology by researching elemental technology in four particular areas related primarily to polymer material technology and secondarily to dispersion technology, coating technology, and coloring technology.

-

Polymer material technology

We are focused on the development of functional polymers by leveraging its structural control technology involving various polymer syntheses and block, graft, and branch polymerization. Moreover, by blending these polymers together, it develops products endowed with various functions (viscoelasticity, refractivity, surface energy, dielectric constant control, etc.).

-

Dispersion technology

We are developing technology related to the dispersion of pigments, nanoparticles, etc. as well as technology that allows for the efficient achievement of surficial functions involving surficial segregation and orientation of active components utilizing dispersion technology.

-

Coating technology

We are developing technology related to paint application and surficial coating. Specific activities include the development of functional inks and printing methods that are suitable for inkjet printing and screen printing, and efficient paint application technology.

-

Coloring technology

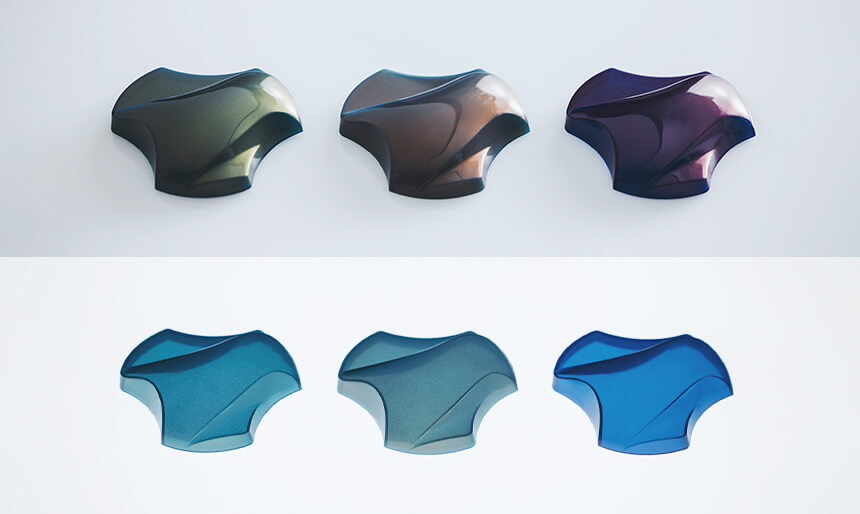

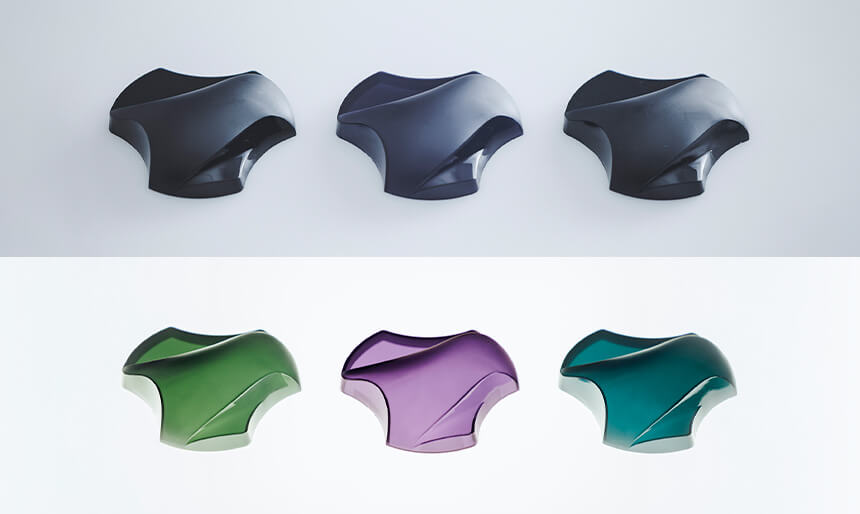

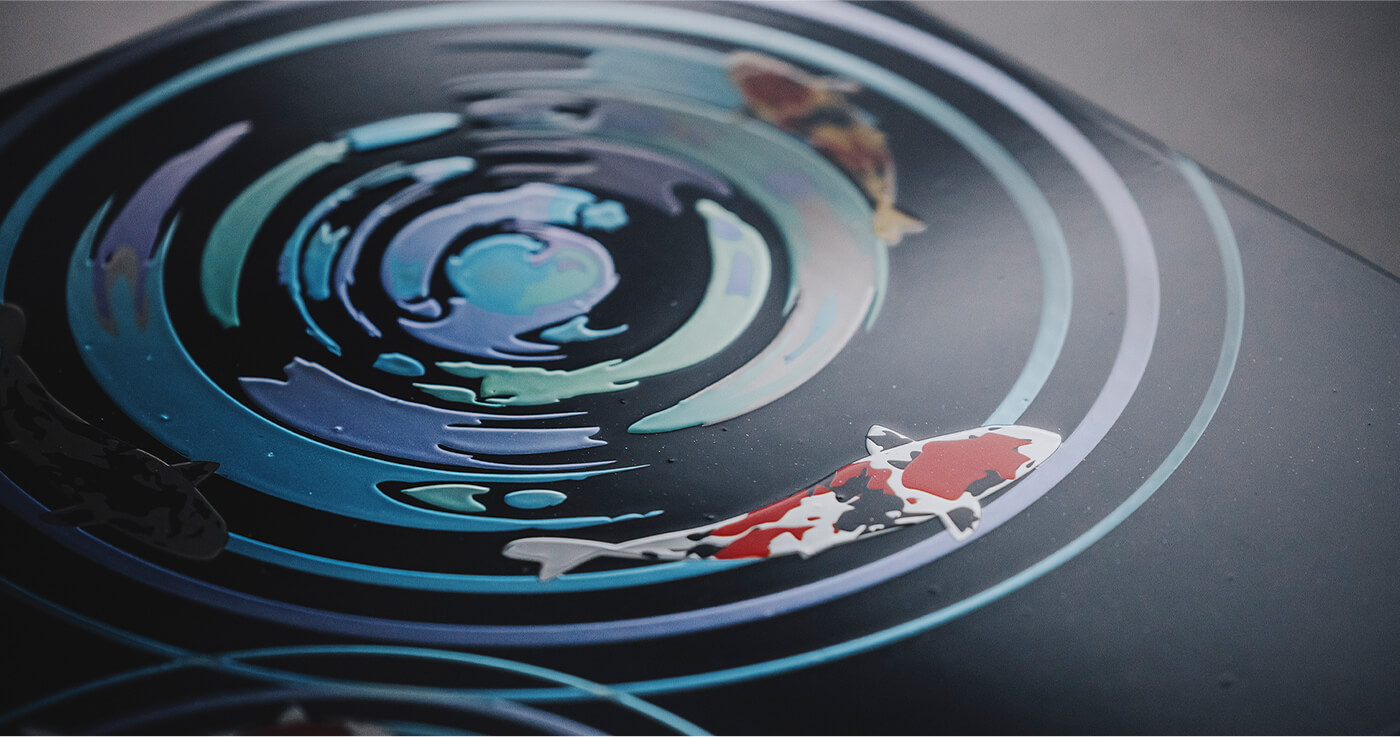

We offer color designs as well as surficial designs and CMF designs* that add novel value in terms of tactile and other surficial qualities.

Applied technology development

-

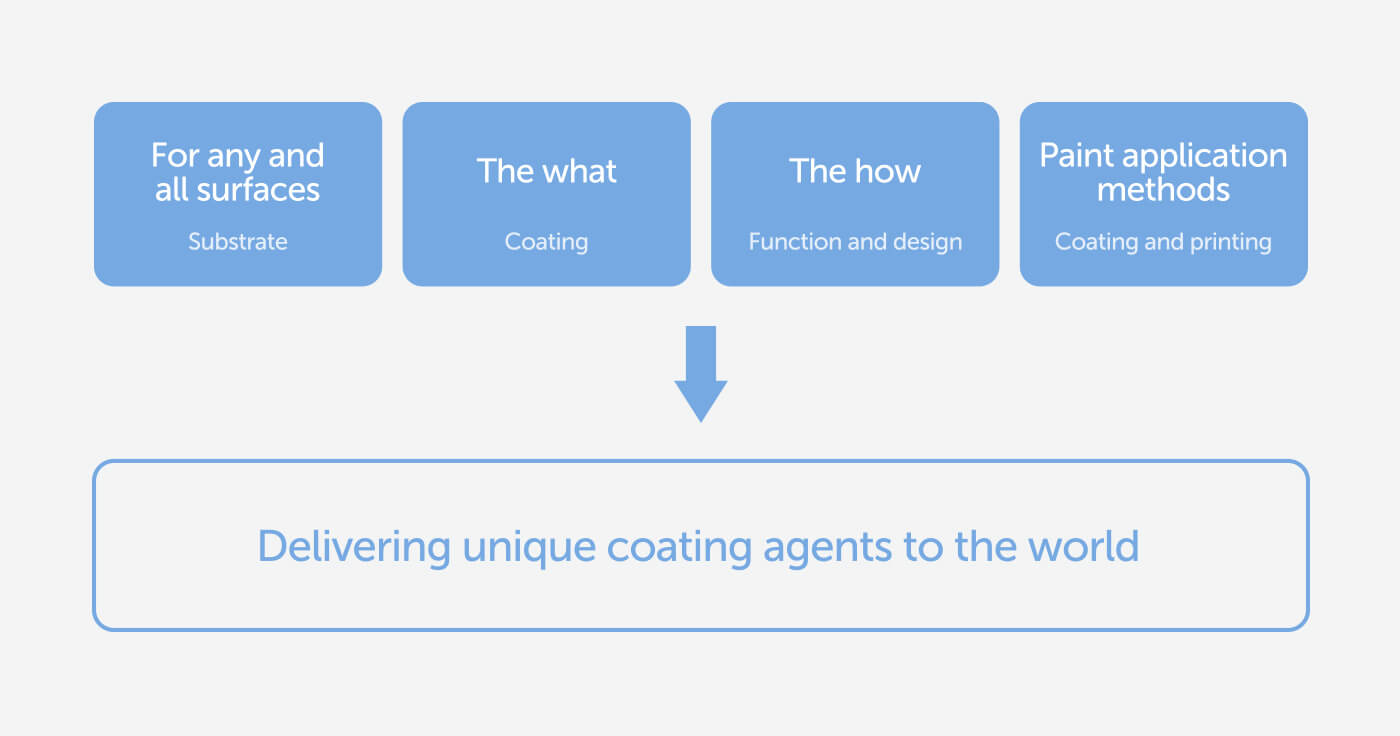

Development of coating agents

We have been honing its technological knowledge and skills – encompassing both basic and applied technologies – related to coating agents to optimize the what and the how of paint application methods for any and all surfaces that exist, by leveraging its elemental technology in dispersion, coating, and coloring mainly related to polymer materials.

-

Ink development for inkjet printing

We have been conducting R&D related to inkjet printing technology and is capable of offering total solutions on primers, base coats, inkjet printing inks, and top coats that are suitable for various substrates. We also closely work with equipment manufacturers and thus can provide suggestions not only on paints and inks but also on print heads, printers, and other hardware. In addition, We are developing on-demand designs that take advantage of the features of inkjet printing in order to become a better total solution provider that can meet any decoration needs.

-

Paintless technology development

As the name implies, paintless technology is the technology that adds functions and designs to the surfaces of materials without involving any paint application. This technology aims to achieve the types of functions that can be actuated and designs that can be expressed only with paints. We have been developing original decorative films and additives for plastic molding so that it can provide unique materials utilizing decoration methods that do not involve paint application.